In the world of custom mechanical keyboards, sterling silver keycaps stand as the pinnacle of luxury and craftsmanship. These exquisite components blend cutting-edge manufacturing with traditional silversmithing techniques, creating functional art for the most discerning enthusiasts. Let us guide you through the fascinating journey of how raw silver transforms into precision keycaps.

1. Material Selection: The 925 Standard

Every precious metal keycap begins with certified 925 sterling silver ingots (92.5% pure silver, 7.5% copper alloy). This centuries-old composition ensures optimal durability while maintaining workability.

- Quality Control: X-ray fluorescence spectroscopy verifies purity, rejecting any ingots with impurities

- Material Cost: Raw silver alone accounts for $12-18 USD per keycap before processing

- Ethical Sourcing: Leading manufacturers now provide conflict-free silver certifications

2. Precision Casting Process

The transformation from ingot to keycap shape employs both ancient and modern techniques:

- Digital Prototyping: 3D-printed resin models achieve 0.05mm precision

- Investment Casting:

- 980°C (1796°F) molten silver poured in vacuum chambers

- Centrifugal force ensures complete mold filling

- Controlled cooling prevents internal stresses

- Post-Casting:

- Sprues carefully removed with laser cutting

- Initial surface inspection under 10x magnification

3. CNC Machining Excellenc

Five-axis CNC mills refine each keycap to perfection:

- Tooling: 0.2mm carbide end mills create crisp edges

- Structural Engineering:

- Internal reinforcement ribs for durability

- Cross-stem tolerances within 0.03mm

- Weight Balancing: Each cap calibrated to ±0.1g

Finished surfaces achieve Ra0.8μm smoothness – smoother than premium watch cases.

4. Surface Finishing Artistry

Master craftsmen employ various techniques to create distinctive finishes:

| Finish Type | Process | Characteristics |

|---|---|---|

| Mirror Polish | Diamond paste hand-polishing | Reflects like liquid mercury |

| Brushed Metal | Directional abrasive brushing | Sophisticated matte texture |

| Glass Bead Blasting | 80-grit microsphere bombardment | Velvety satin appearance |

| Antique Patina | Controlled sulfur oxidation | Vintage “heirloom” effect |

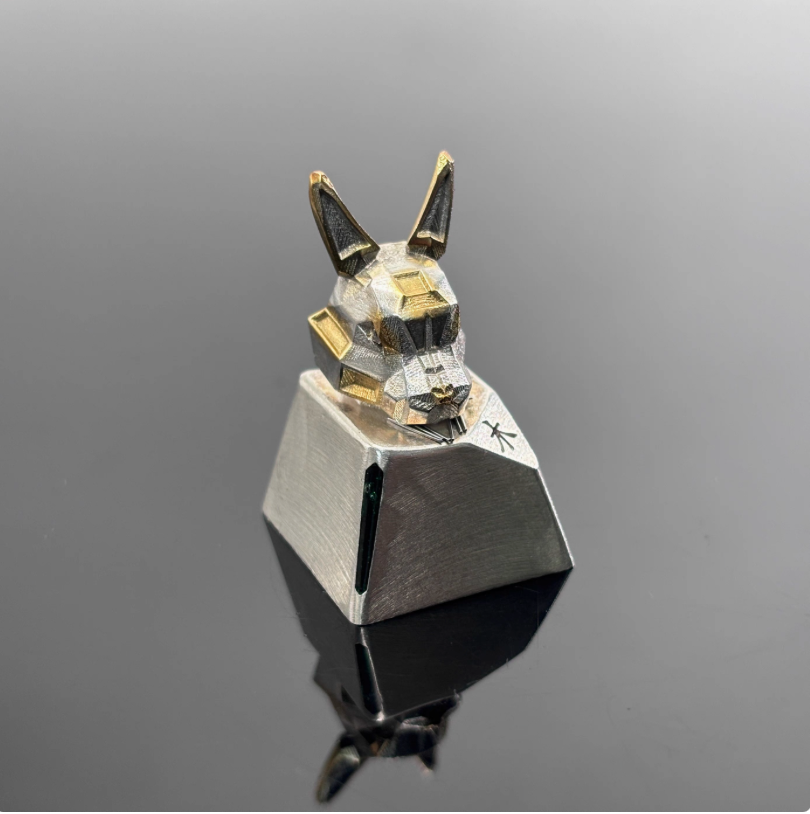

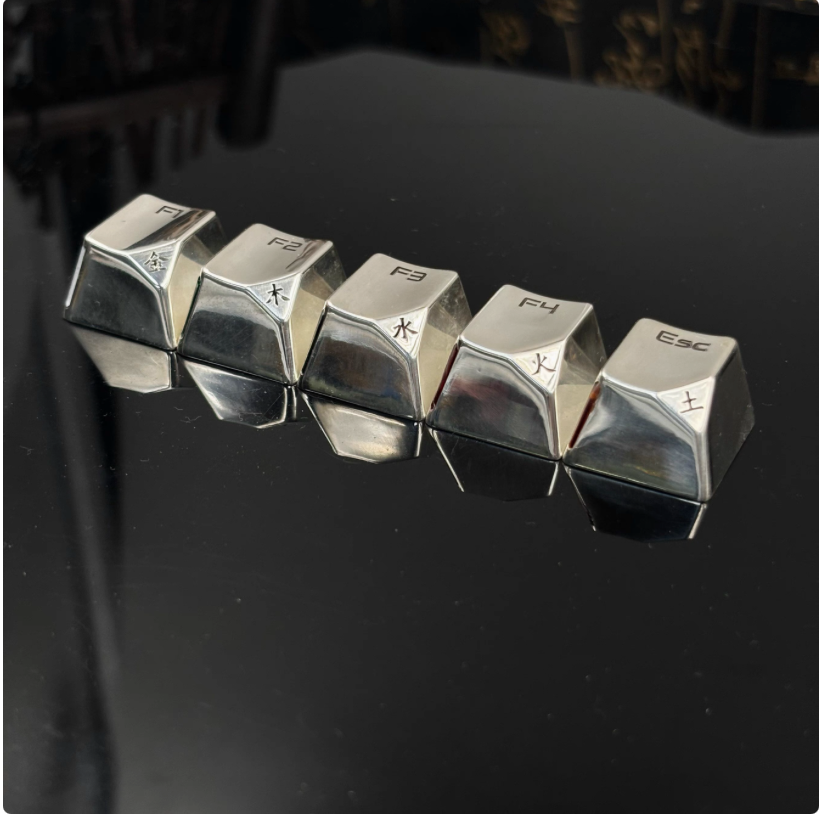

Special editions may feature:

- 24K gold inlays

- Laser-engraved serial numbers (0.1mm precision)

- Custom enamel fillings

5. Rigorous Quality Assurance

Every solid silver keycap undergoes exhaustive testing:

- Dimensional Checks:

- Height tolerance: ±0.1mm

- Stem fit tested on 10+ switch types

- Durability Testing:

- 500,000 keystroke simulation

- Salt spray corrosion resistance

- Thermal Cycling: -20°C to 60°C (-4°F to 140°F) exposure

6. Artisanal Final Touches

Even after precision machining, human expertise remains irreplaceable:

- Hand-Polishing: Chamfered edges buffed with deer leather

- Micro-Inspection: 20x loupe examination for flawless surfaces

- Personalization: Monogram engraving or custom motifs

Each completed keycap receives:

✔ Individually numbered certificate

✔ 925 purity hallmark

✔ Premium anti-tarnish packaging

The Making of a Modern Heirloom

Transforming 25-30g of silver into a functional masterpiece requires:

- 18-25 hours of skilled labor

- 22 distinct production stages

- 14 quality control checkpoints

These handcrafted silver keycaps represent more than typing tools – they’re wearable art for your keyboard, blending centuries-old metallurgy with contemporary design. Whether displayed in a collector’s case or gracing a daily driver, each piece carries the legacy of precision craftsmanship into the digital age.

For enthusiasts seeking the ultimate keyboard customization, sterling silver keycaps offer unmatched sophistication – where every keystroke echoes with the weight of luxury.

Welcome to follow us on Facebook to know our latest series and new products